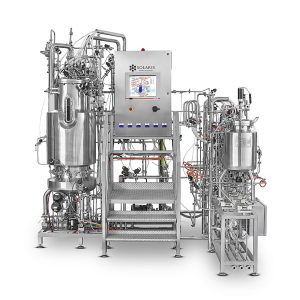

S-I Series Fermenters/Bioreactors have been created with the intention to face all the problems related to scaling-up, from the laboratory to production stage, with maximum ease.

- Customisable culture vessels from 5 L to 30,000 L

- Instrumentation for control and measurement of pH, dO2, CO2, RPM, gas mixing, temperature, anti-foam, feeds, total cell density and viable cell density measurement, weight, redox, conductivity, Level, etc.

- SCADA Control System SBC-16

- Software management data – trends

- Designed for microbial and cell fermentation, for batch, fed-batch and continuous processes

- Complete range of accessories

- Brushless motor for agitation system

The S and I series consist of highly automated pilot-industrial fermenters and bioreactors, available from 5 up to 30,000 litres and more (S series 5 – 200 L; I series 300 – 30,000 L). These fermentation units are completely customisable, tailor-made starting from the clients’ specific requests.

Matt’s take on this product

Experience the future of fermentation with the S and I series, where innovation meets your unique vision.

Introducing the S and I Series. Our highly automated pilot-industrial fermenters and bioreactors, available in a wide range of capacities, from 5 L up to an impressive 30,000 L (S series: 5-200 L; I series: 300-30,000 L), are designed to meet your exact needs. The S and I series boast complete customisability, tailored specifically to your requirements and preferences. From the initial consultation, we work closely with you to create a solution that aligns perfectly with your specific requests.

Specialist: Solaris not only offers off-the-shelf systems, but turnkey solutions for their customers. They can assist their clients in the design and manufacturing of completely integrated turn-key process plants for nearly any application, whether that be biopharma, biotech, food and beverage, and many more. .

Did you know?

You can maximise you R&D capabilities by run up to 24 units in parallel using the Leonardo software.

Make an enquiry

SIP and CIP Customisable Pilot and Industrial Scale Fermenters/ Bioreactors

The Solaris S-I can be used for; Pilot scale process development, Scale up and scale-down studies and production.

Features & Benefits

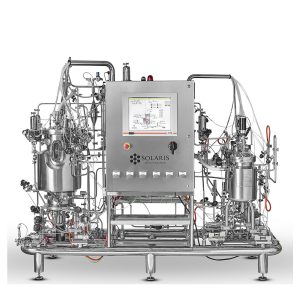

- Top quality stainless steel with excellent finishing and high technology.

- Insulated vessels, with the possibility of passivation.

- Different H/D ratios.

- Different types of finishing (mirror polish, scotch brite, electropolishing, etc.).

- Different types of agitation (top-bottom, single or double mechanical seal with lubrication loop, magnetic stirrer).

- Different types of thermoregulation loops (from basic to completely closed).

- Microbial (aerobic, anaerobic) and cell cultures configurations available.

- Suitable for batch, fed-batch and continuous processes.

- Several gas mixing strategies with a selectable number of rotameters, TMFCs or solenoid valves, for air, O 2, CO 2 and N 2.

- Wide range of measurement and control options including temperature, pH, dO 2, dCO 2, redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells), etc.

- Modbus digital sensors.

- Stainless-steel industrial PCS LEM_2, with a selectable number and type of peristaltic pumps.

- cGMP certifiable.

- Easy to access service lines, to easily perform maintenance.

- The systems can be integrated with tanks (feeding tanks, mixing tanks, harvest tanks, etc.), CIP/SIP systems, centrifuges, filtration systems, and many more ancillary equipment.