The BPES full product catalogue

Cell Imaging & Analysis

SYNENTEC NyONE Compact Cell Imager

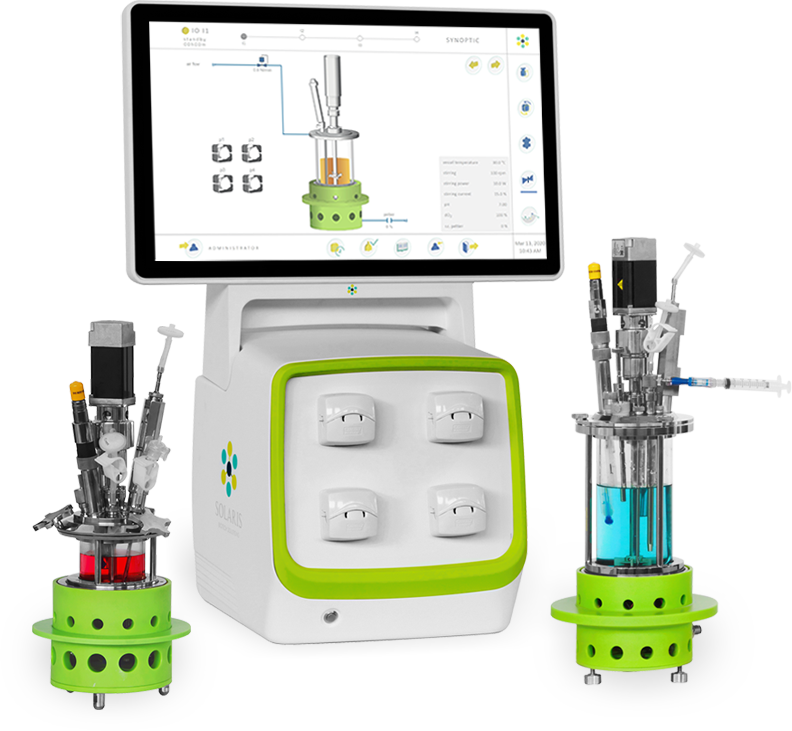

Bioreactors & Fermenters

Solaris IO 200-1000mL – Benchtop Mini Bioreactors & Fermenters

Shake Flasks and Consumables

Thomson Ultra Yield Flask – 125mL to 2.5L

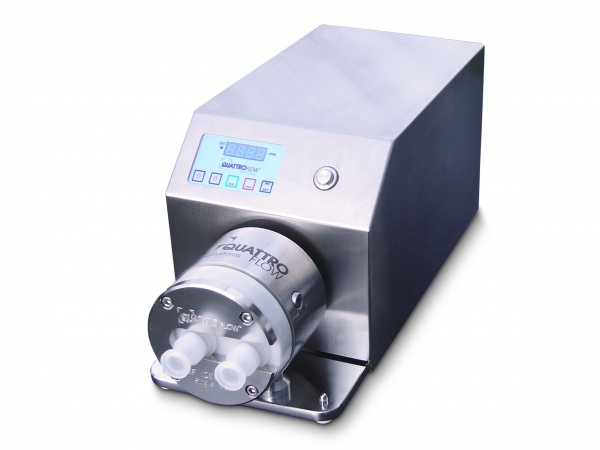

Biotech Pumps

Quattroflow QF30SU Single-Use Biotech Pump

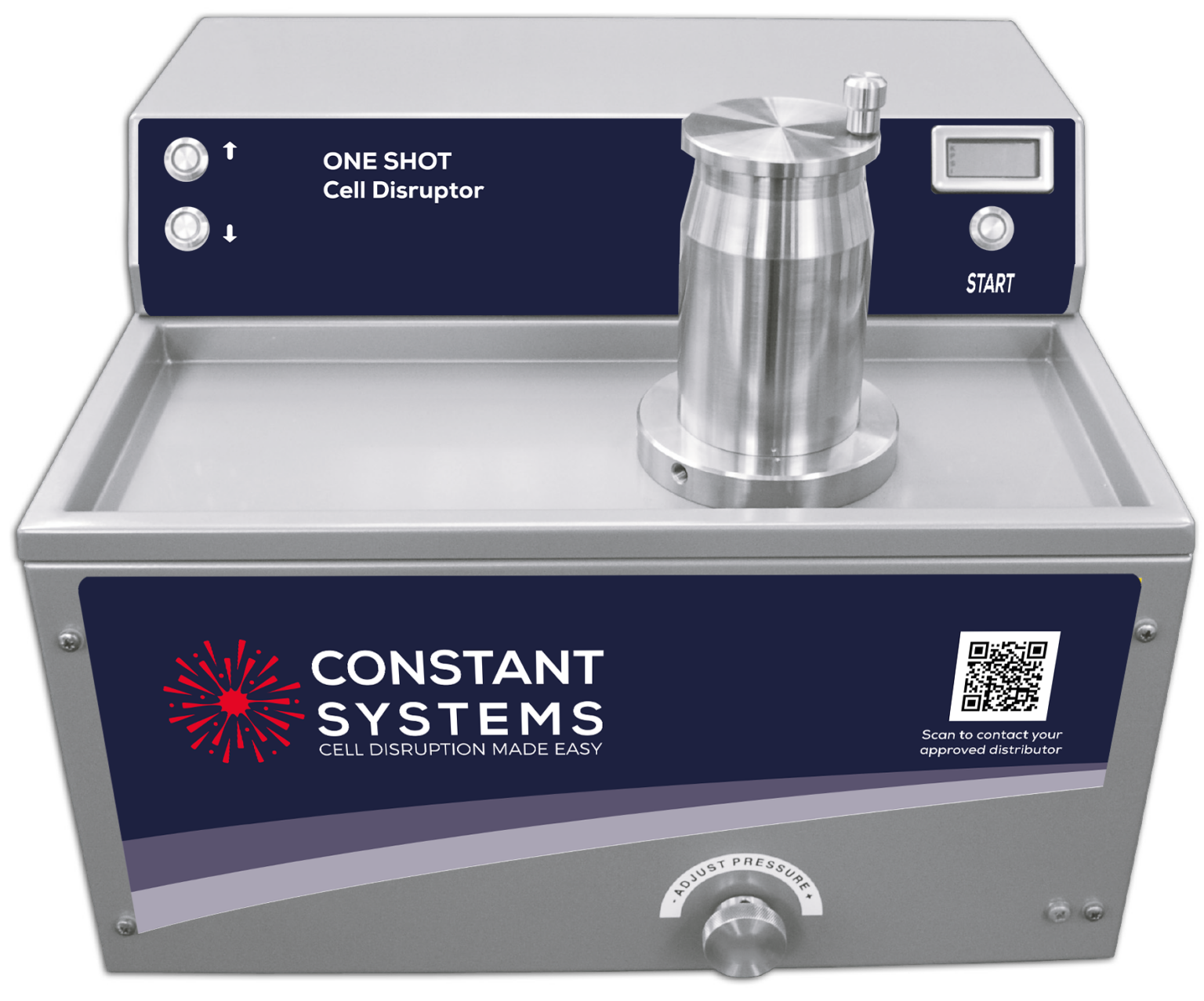

Cell Disruptors

One Shot Cell Disruptor 0.5mL to 8mL

Bioreactors & Fermenters

Solaris Jupiter 2-10L – Autoclavable Benchtop Fermenters & Bioreactors

Biotech Pumps

Quattroflow QF150 Biotech Pump

Cell Disruptors

Multi Cycle Cell Disruptor 0.5mL to 80mL

Shake Flasks and Consumables

Thomson Optimum Growth Flask – 125mL to 7L

Biotech Pumps

Quattroflow QF1200 Biotech Pump

Cell Disruptors

Continuous Flow Cell Disruptors up to 6L/hr & 24L/hr

Shake Flasks and Consumables

Thomson Sampling Flasks

Bioreactors & Fermenters

Solaris ONE – Single Wall Fermenters / Bioreactors

Cell Disruptors

High Flow Rate Cell Disruptor up to 150L per hour

Bioreactors & Fermenters

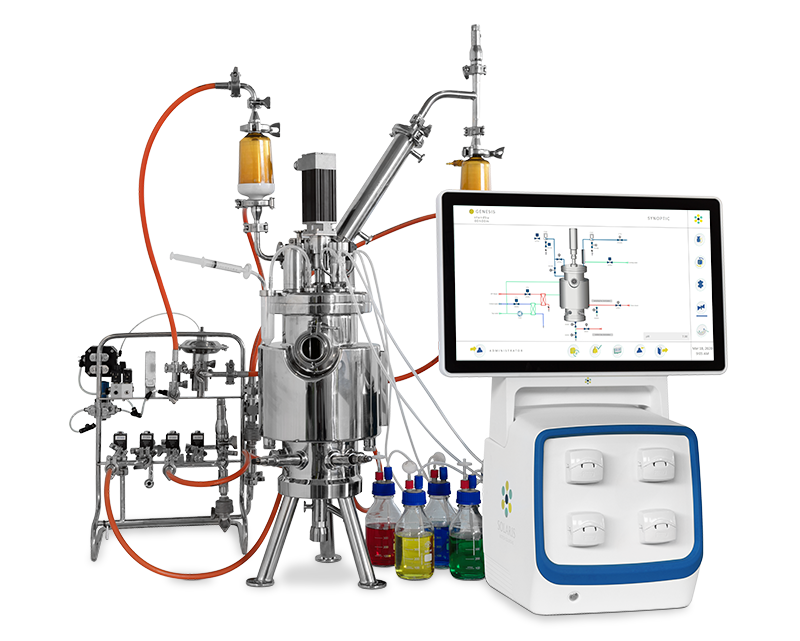

Solaris Genesis 7.5-20L – SIP Benchtop Bioreactor & Fermenter

Shake Flasks and Consumables

Thomson Multiport Flasks