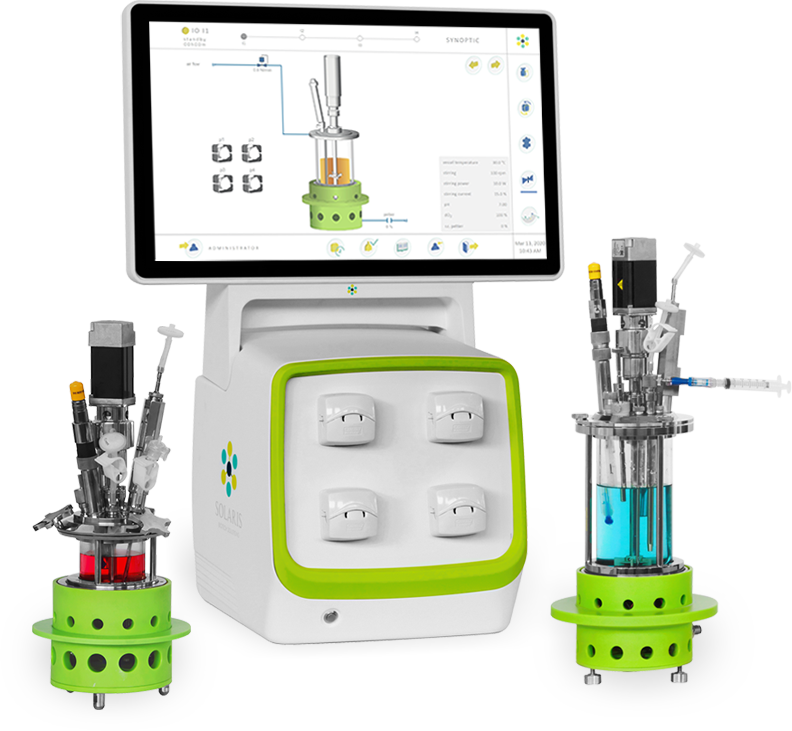

IO is a fully electric mini fermenter/bioreactor featuring a rapid and precise thermoregulation system that operates without the need for water circulation. With total volumes of either 200ml or 1000ml, it represents a cutting-edge device for process development and media optimisation.

- The ideal device for innovative parallel process development

- Total volumes 200 mL and 1000 mL

- 2 different ratios

- Ideal for applications including:

- Cell and strain screening

- Protein expression and kinetics

- Fermentation optimisation

- Synthetic biology

- Enzyme activity tests

Matt’s take on this product

Revolutionise your lab with the IO – compact, powerful, and designed to elevate your research to new heights.

Introducing the IO, Solaris’ smallest benchtop fermenter/bioreactor option available in 200 ml and 1000 ml volumes. What sets the IO apart is its ultra-compact design, maximising precious lab space while delivering exceptional performance. Ideal for R&D with expensive media, the IO offers cost-effective solutions without compromising on quality. Experience the IO’s innovative thermoregulation system, powered by a Peltier Cell.

Say goodbye to external water supplies as the IO efficiently heats and cools, simplifying your workflow and utility requirements.

Did you know?

You can maximise you R&D capabilities by run up to 24 units in parallel using the Leonardo software.

Make an enquiry

Single & parallel autoclavable stirred mini-fermenter/bioreactor

The Solaris IO can be used for; process development and optimisation, education, basic research, scale-up and scale-down studies and small production.

Solaris IO features & benefits

- Single-wall borosilicate glass vessel, with thermoregulation performed through a Peltier Cell (no need for an external chiller/water supply).

- Different configurations available for microbial (aerobic/anaerobic) and cell culture applications, with the choice of Rushton/Marine/Pitched-Blade impellers and fluted/L-shaped sparger.

- Wide range of measurement and control options, including temperature, pH, dO 2 , dCO 2 , redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells).

- Modbus digital sensors reduce background noise and guarantee quick response time.

- Suitable for batch, fed-batch and continuous processes.

- Powerful and accurate (1 RPM) brushless motor.

- Optional integration of up to 4 analog input/output connections, choosing between 0-10 V and 0-20 mA/4-20 mA (e.g. pumps or valves with power supply independent from Solaris electrical cabinet)

- Different gas mixing strategies with up to 5 TMFC and/or solenoid valves.

- Gas out can be optionally integrated with a condenser with Peltier Cell.

- Extremely compact system maximizes lab space.

Solaris IO software

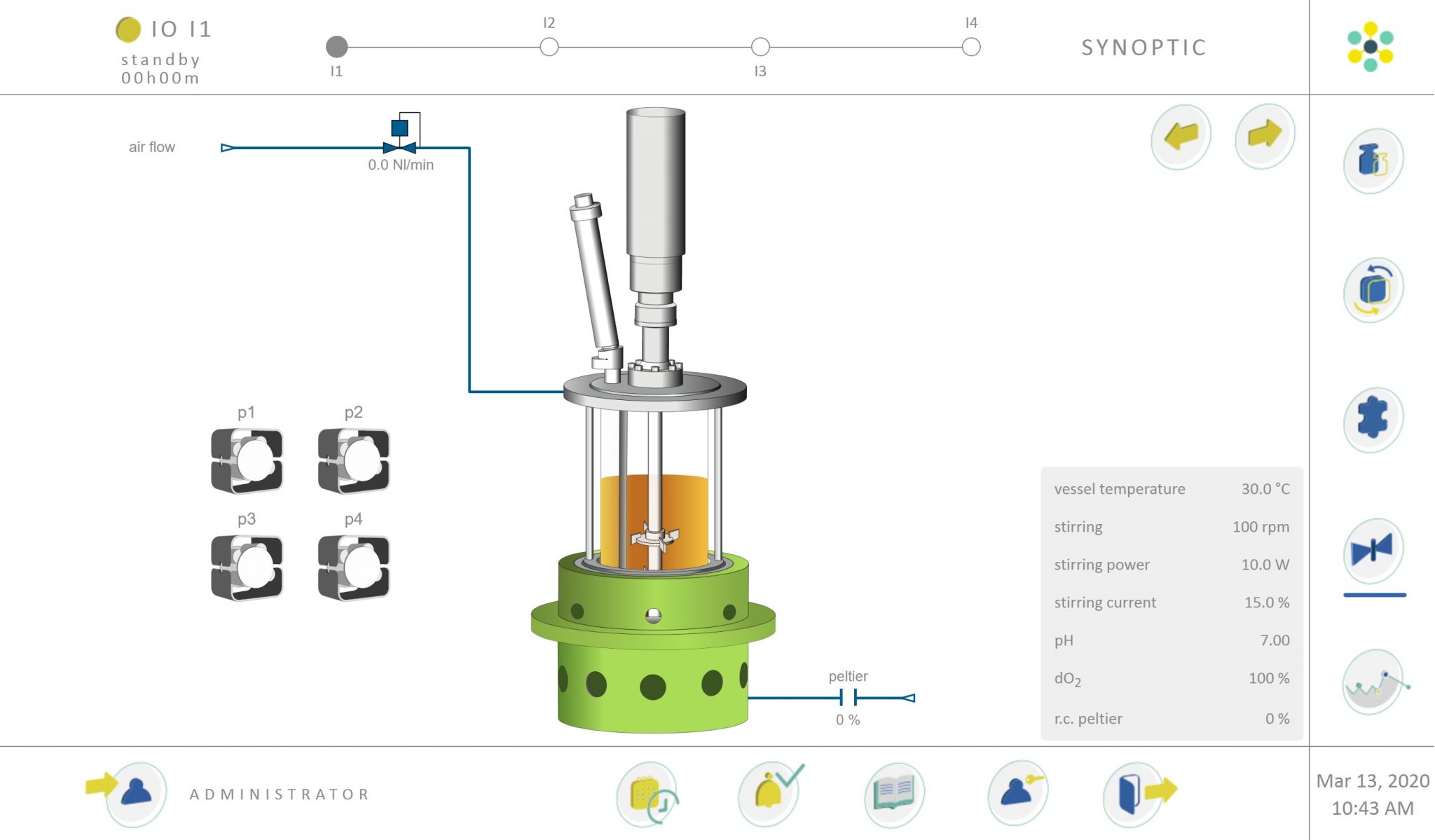

- Innovative SCADA software LEONARDO 3.0: a smart and user-friendly controller designed to provide a high level of automated management of the fermentation/cultivation processes.

- Full version included in the equipment supply.

- Up to 24 units managed in parallel with a unique HMI (24”).

- Data extraction in .csv format.

- Remote access via PC, tablet or smartphone, with QR code scanning or dedicated portal.

- Remote control for after sale assistance.