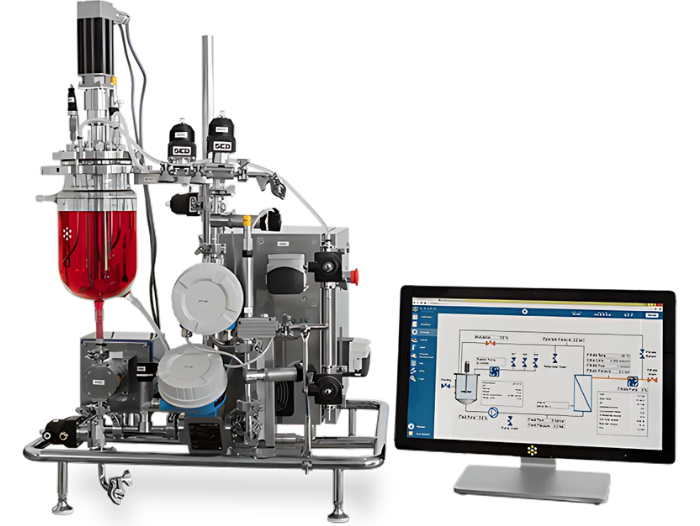

Solaris Biotech benchtop fermenters and bioreactors offer efficient platforms for R&D and product development applications. Their broad range of products are flexible and easy to use, ensuring there is always a solution specific to your needs and requirements – from research scale of a few hundred ml up to cGMP production of > 2000L.

Benefits include compact and user friendly designs, parallel software platform, up-to-date and open communication protocols.

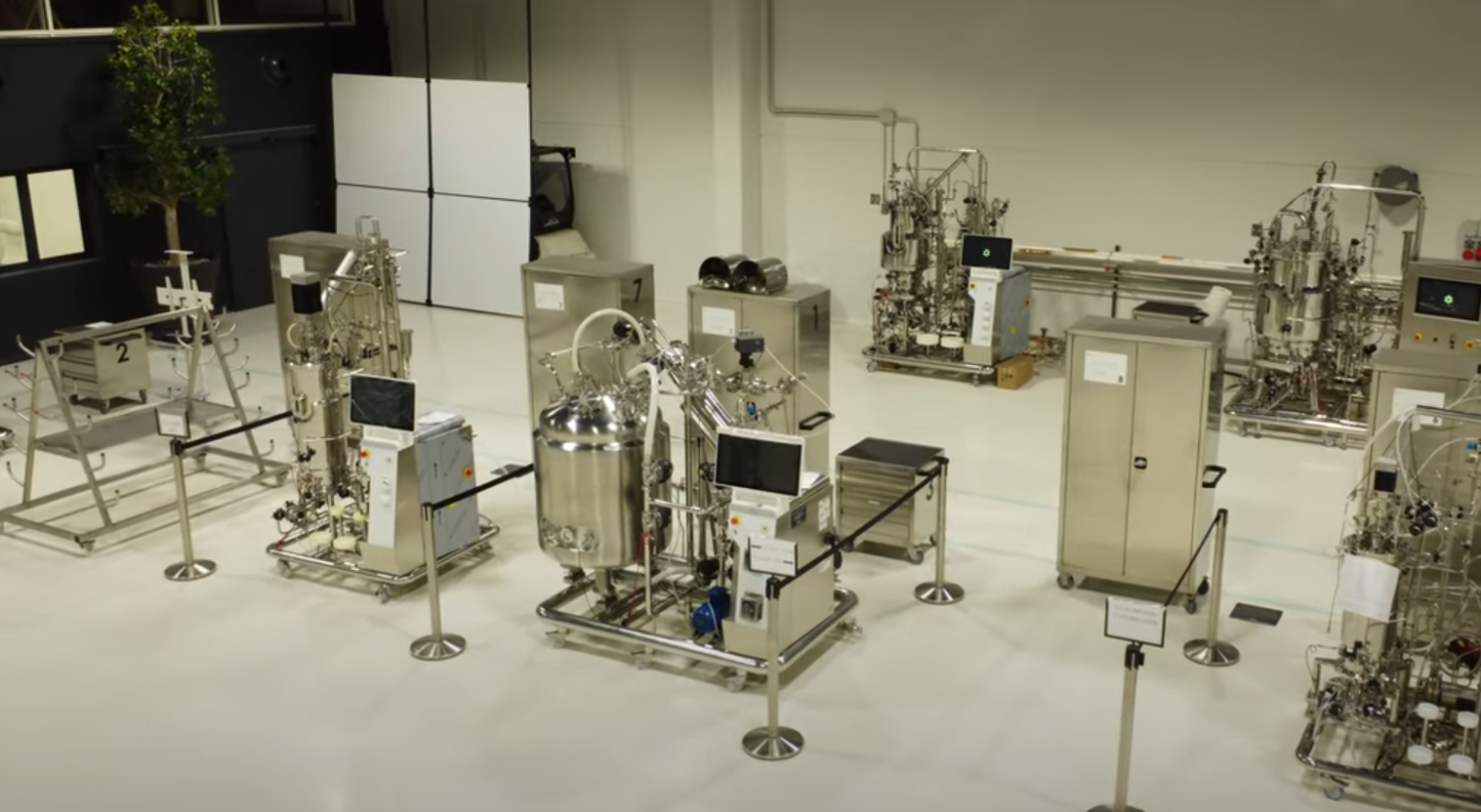

The product range is used in universities, schools and research centres, as well as in pharma, nutraceutical, cosmeceutical, chemical, agricultural, and food and beverage industries, not to mention bioplastics and biofuels applications.

Solaris Tangential Flow Filtration (TFF) systems, fully automated within the Kronos product line, combine industrial elements and a compact design. For larger scale TFF applications open to customisation, consider the Tytan platform.

Read the latest Solaris Biotech publications

More on Solaris Biotech

Solaris Biotech products

Bioreactors & Fermenters

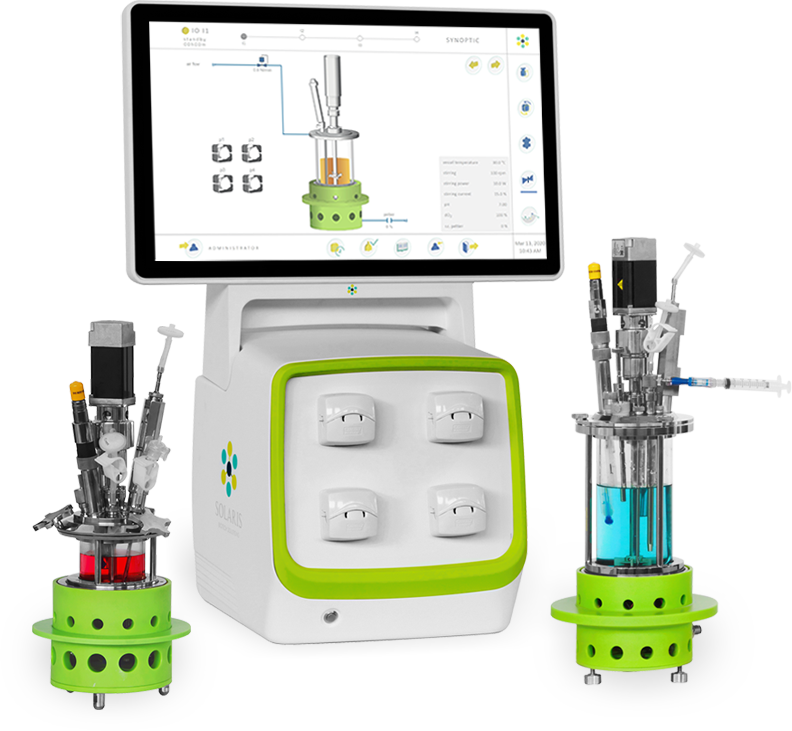

Solaris IO 200-1000mL – Benchtop Mini Bioreactors & Fermenters

Bioreactors & Fermenters

Solaris Jupiter 2-10L – Autoclavable Benchtop Fermenters & Bioreactors

Bioreactors & Fermenters

Solaris ONE – Single Wall Fermenters / Bioreactors

Bioreactors & Fermenters

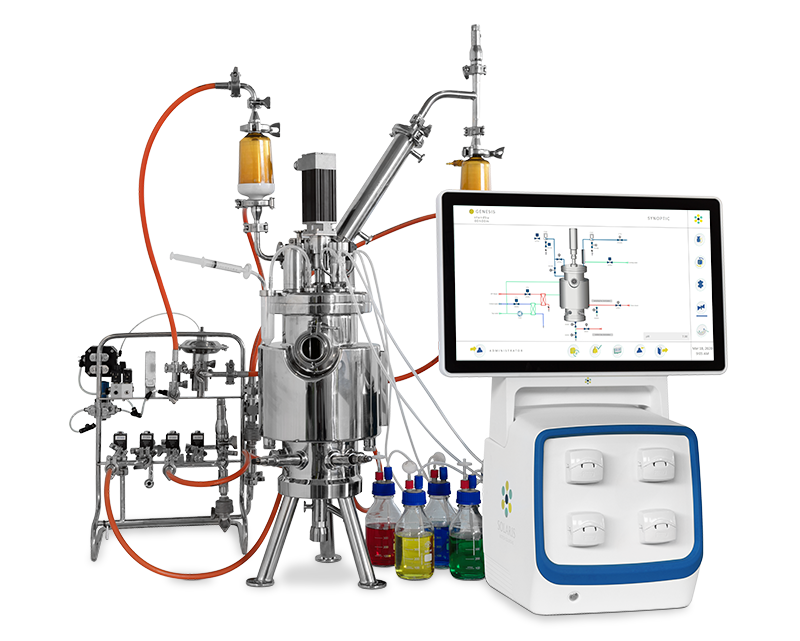

Solaris Genesis 7.5-20L – SIP Benchtop Bioreactor & Fermenter

Bioreactors & Fermenters

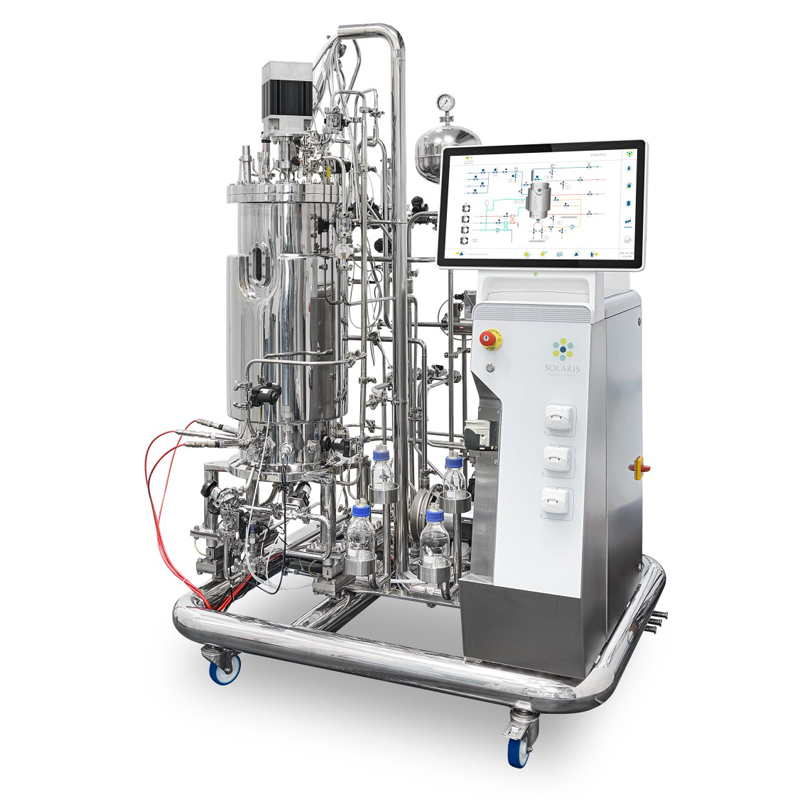

Solaris M-Series 30-200L – SIP Fermenters & Bioreactors

Bioreactors & Fermenters

Solaris S-I Series – Customisable Pilot and Industrial Scale Fermenters & Bioreactors

Bioreactors & Fermenters

Solaris Elara – Laboratory Benchtop Photobioreactor

Downstream Processing

Solaris Kronos – Benchtop TFF Systems

Downstream Processing

Solaris Tytan – Pilot Industrial TFF Systems