Description

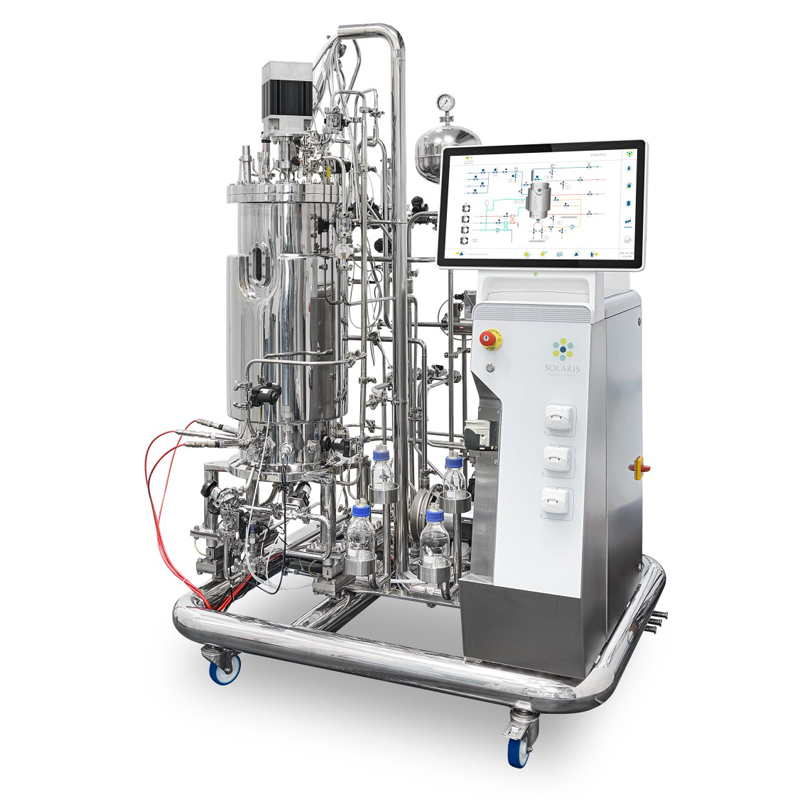

Solaris GENESIS: Single and Parallel Standard SIP Fermenter/Bioreactor

The S and I series consist of highly automated pilot-industrial fermenters and bioreactors, available from 5 up to 30,000 litres and more (S series 5 – 200 L; I series 300 – 30,000 L). These fermentation units are completely customisable, tailor-made starting from the clients’ specific requests.

- Customisable culture vessels from 5 L to 30,000 L

- Instrumentation for control and measurement of pH, dO2, CO2, RPM, gas mixing, temperature, anti-foam, feeds, total cell density and viable cell density measurement, weight, redox, conductivity, Level, etc.

- SCADA Control System SBC-16

- Software management data – trends

- Designed for microbial and cell fermentation, for batch, fed-batch and continuous processes

- Complete range of accessories

- Brushless motor for agitation system

Fermenters / Bioreactors

SIP and CIP Customisable Pilot and Industrial Scale Fermenters/ Bioreactors

The Solaris S-I can be used for; Pilot scale process development, Scale up and scale-down studies and production.

Features

- Top quality stainless steel with excellent finishing and high technology.

- Insulated vessels, with the possibility of passivation.

- Different H/D ratios.

- Different types of finishing (mirror polish, scotch brite, electropolishing, etc.).

- Different types of agitation (top-bottom, single or double mechanical seal with lubrication loop, magnetic stirrer).

- Different types of thermoregulation loops (from basic to completely closed).

- Microbial (aerobic, anaerobic) and cell cultures configurations available.

- Suitable for batch, fed-batch and continuous processes.

- Several gas mixing strategies with a selectable number of rotameters, TMFCs or solenoid valves, for air, O 2, CO 2 and N 2.

Benefits

- Wide range of measurement and control options including temperature, pH, dO 2, dCO 2, redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells), etc.

- Modbus digital sensors.

- Stainless-steel industrial PCS LEM_2, with a selectable number and type of peristaltic pumps.

- cGMP certifiable.

- Easy to access service lines, to easily perform maintenance.

- The systems can be integrated with tanks (feeding tanks, mixing tanks, harvest tanks, etc.), CIP/SIP systems, centrifuges, filtration systems, and many more ancillary equipment.

Downloads

More on Solaris

Solaris Biotech benchtop fermenters and bioreactors offer efficient platforms for R&D and product development applications. Their broad range of products are flexible and easy to use, ensuring there is always a solution specific to your needs and requirements – from research scale of a few hundred ml up to cGMP production of > 2000L.

Benefits include compact and user friendly designs, parallel software platform, up-to-date and open communication protocols.

The product range is used in universities, schools and research centres, as well as in pharma, nutraceutical, cosmeceutical, chemical, agricultural, and food and beverage industries, not to mention bioplastics and biofuels applications.

Solaris Tangential Flow Filtration (TFF) systems, fully automated within the Kronos product line, combine industrial elements and a compact design. For larger scale TFF applications open to customisation, consider the Tytan platform.