Description

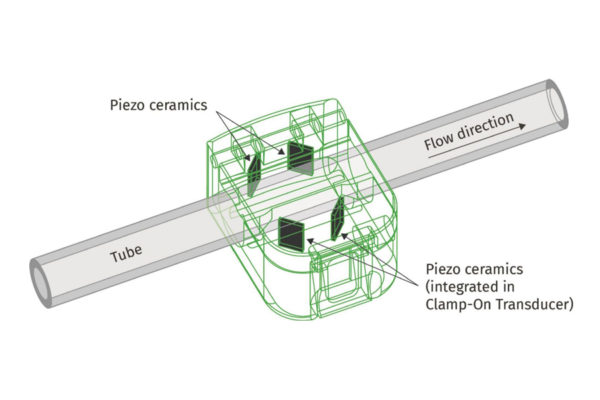

The function is based on the ultrasonic transit-time method and works non-invasively, meaning there is no direct contact with the medium, the flow transducer simply clamps onto the outside of flexible tubing making it particularly suitable for processes with strict hygienic requirements and single use flow paths.

BioProTT™ FlowTrack SL

The benchtop version consisting of the evaluation device BioProTT™ FlowTrack plus and the corresponding BioProTT™ Clamp-On Transducer is ideally geared for the independent monitoring of flows within the laboratory suite.

The easily readable display of the BioProTT FlowTrack plus shows the current flow rate, while a direct data transfer to the computer is possible through the RS-232 interface as well as through an analog interface.

Application

- Flow measurement on flexible tubes

- Control of the upstream feed

- Evaluation and upscaling of processes

- Flow monitoring during chromatographies or filtrations on a laboratory scale

- Fillings

- Control of process equipment such as pumps or valves

Key Facts

- Monitoring of the volume flow rate in real time through the integrated display

- Digital (RS-232) and analog interface for the data transfer to a computer

- Linear adjustment of the pre-installed sensor calibration by using a factor

- Compact, space-saving design – ideal for applications within laboratories

- Dust-tight and protected on all sides from spray (IP 65)

- Totalisation function

BioProTT™ FlowMCP

Depending on the version, it is possible to measure and monitor up to eight flow channels at the same time. Every BioProTT FlowMCP works in combination with our BioProTT Clamp-On Transducers. With its space-saving design and convenient top hat rail mounting, the BioProTT FlowMCPs can be optimally integrated into the switch cabinet.

Their full compatibility with all BioProTT Clamp-On Transducers also ensures that the BioProTT FlowMCPs can be used in existing systems and equipment within the industrial field. Through the MCPs and a Modbus-TCP log, the measured data of up to eight sensors is fed into the customer-specific process control system. This ensures, for instance, that, depending on the programming, the pump speed or the valves are controlled.

Application

- Flow measurement on single-use equipment

- Adding media at bioreactors

- Fillings

- Upscaling

- Control of process equipment

- Chromatographies

- Filtrations

- Process evaluation

- Research

Key Facts

- Space-saving switch cabinet design

- Different BioProTT FlowMCP variants ranging from one to four flow channels

- Seamless integration into existing systems

- Web interface to check sensor calibration and to zero the flow value

- Full compatibility with all sizes of the BioProTT Clamp-On Transducers

- Linear adjustment of the pre-installed sensor calibration through a calibration factor

- Modbus-TCP log to feed data into the customer specific process control system (coming soon: analog interface)

BioProTT™ Clamp-On SL

In combination with the BioProTT™ Flowtrack SL or a BioProTT™ MCP, the BioProTT™ Clamp-On SL ensures a reliable monitoring of the volume flow rate within the laboratory suite.

Using a click-fastening, the transducer can be easily and quickly connected to flexible tubes, making it unnecessary to splice the product line. This avoids both contamination as well as a drop in pressure. The non-invasive, functional design without movable parts prevents additional shear stress on the medium, which is an essential advantage compared to invasive methods when it comes to handling shear-sensitive organisms and molecules.

The applied ultrasonic transit-time method, combined with a customer-specific calibration with regard to the respective process parameters, allows for a highly accurate measurement in addition to flexible application opportunities.

Application

- Chromatographies

- Process evaluation

- Fillings

- Filtration

- Adding media at bioreactors

- Upscaling

Key Facts

- Easy installation, non-invasive flow measurement

- Customer specific calibration to tube, medium, temperature, and maximum flow rate

- Different sensor sizes for all commonly used tube sizes ranging from ¼” to 1-5/8” outer diameter

- Up to seven calibration tables storable on one sensor—for maximum flexibility

- No additional shear stress on cells through the non-invasive design

- Easily cleaned with commonly available disinfectants

- Re-usable and longlasting

Further Information

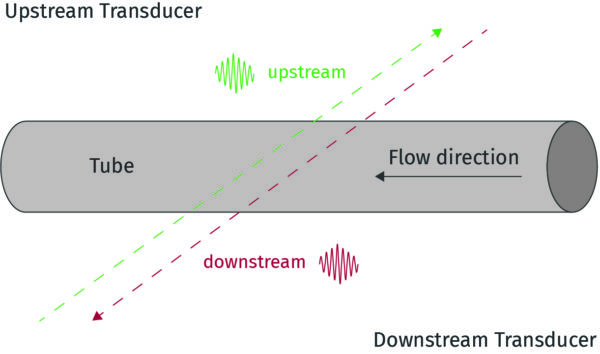

Through the operating principle of the ultrasonic transit time difference method, the flow measurement is non-invasive, meaning without direct contact to the medium

When sending ultrasonic sound signals through the measuring section, the transit time difference depends on the flow direction of the medium:

- If the ultrasonic sound signals are sent along the flow direction, the downstream signal needs less time.

- If the ultrasonic sound signals are sent against the flow direction, the upstream signal needs more time

- The evaluation of the received ultrasonic signals is based on the upstream and the downstream measuring section.

Consequently, the transit time difference is measured for every pulse. The difference between upstream and downstream measurements is proportional to the volumetric flow rate.

More on PSG Biotech

PSG Biotech products are ideal for use in all stages of biopharmaceutical manufacturing – Laboratory, Upstream and Downstream – and in such critical applications as buffer and media preparation, small-scale liquid handling, bioreaction and centrifugation, depth filtration, cell cultivation, chromatography, in-line buffer formulation, tangential flow filtration (TFF), virus filtration and bulk container filling.