Description

Features

- Wide range of options with volumes from 2-10 L.

- Intelligent sensors

- Wireless connection

- Easyload pumps

- Aeration module conveniently located

- Ideal for microbial fermentation as well as animal, plant and insect cell cultivation

- Process development and optimisation

- Scale up/down studies

- Basic research

- Available as a jacketed or single walled vessel

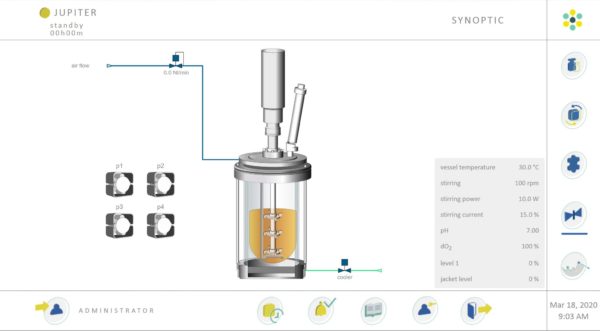

Single & parallel autoclavable stirred mini-fermenter/bioreactor

The Solaris Jupiter can be used for; process development and optimisation, education, basic research, scale-up and scale-down studies and small production.

Solaris Jupiter features & benefits

- 5 different volumes (2 L, 4 L, 6.5 L, 8 L, 10 L) and 2 different ratios H/D.

- Jacketed and single-wall borosilicate glass vessel designs available for all volumes.

- Microbial (Toro sparger, Rushton impellers, baffles) and cell cultures (Sintered sparger, Marine impellers, baffles caps) configurations available.

- Wide range of measurement and control options, including temperature, pH, dO 2 , dCO 2 , redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells).

- Modbus digital sensors reduce background noise and guarantee quick response time.

- Suitable for batch, fed-batch and continuous processes.

- Powerful and accurate (1 RPM) brushless motor.

- Optional integration of up to 4 analog input/output connections, choosing between 0-10 V and 0-20 mA/4-20 mA (e.g. pumps or valves with power supply independent from Solaris electrical cabinet).

- Different gas mixing strategies with up to 5 TMFC and/or solenoid valves.

- Jacketed design: fully removable and cleanable glass jacket for improved heat transfer during autoclaving.

- Single-wall design: thermoregulation performed with heating blanket and cooling finger.

- Pressure control up to 1.6 bar (with constant gas-in and gas-out flux) available in the 2 and 4 L volumes with jacketed design.

Solaris Jupiter software:

- Innovative SCADA software LEONARDO 3.0: a smart and user-friendly controller designed to provide a high level of automated management of the fermentation/cultivation processes.

- Full version included in the equipment supply.

- Up to 24 units managed in parallel with a unique HMI (24”).

- Data extraction in .csv format.

- Remote access via PC, tablet or smartphone, with QR code scanning or dedicated portal.

- Remote control for after sale assistance.

Downloads

More on Solaris

Solaris Biotech benchtop fermenters and bioreactors offer efficient platforms for R&D and product development applications. Their broad range of products are flexible and easy to use, ensuring there is always a solution specific to your needs and requirements – from research scale of a few hundred ml up to cGMP production of > 2000L.

Benefits include compact and user friendly designs, parallel software platform, up-to-date and open communication protocols.

The product range is used in universities, schools and research centres, as well as in pharma, nutraceutical, cosmeceutical, chemical, agricultural, and food and beverage industries, not to mention bioplastics and biofuels applications.

Solaris Tangential Flow Filtration (TFF) systems, fully automated within the Kronos product line, combine industrial elements and a compact design. For larger scale TFF applications open to customisation, consider the Tytan platform.