Description

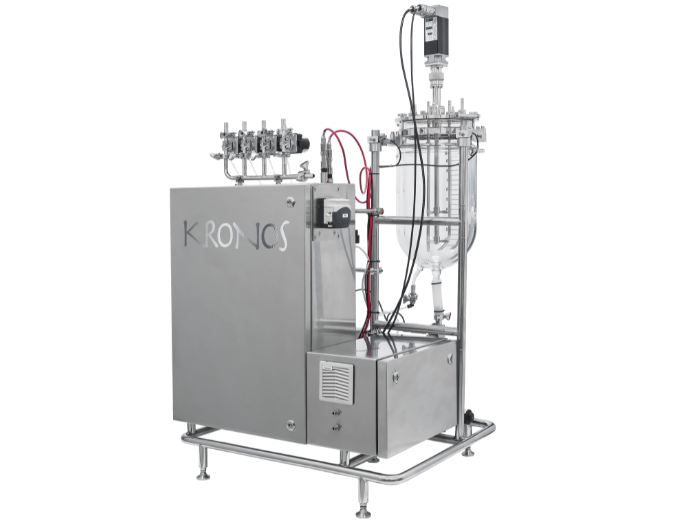

The Solaris Kronos can handle up to 0.5 m2 total filtration area and is equipped with multiple modules make it so the ideal system for innovative process development as long as for automatic process sequence. Kronos meets your specific needs, it covers a wide range of applications such batch and fed batch ultrafiltration, micro filtration and diafiltration.

- Available in 3 different volumes: 2L, 5L, 10L.

- Jacketed and autoclavable glass vessel.

- It can be equipped with several types of membranes (hollow fiber, cassettes, ceramic, etc.)

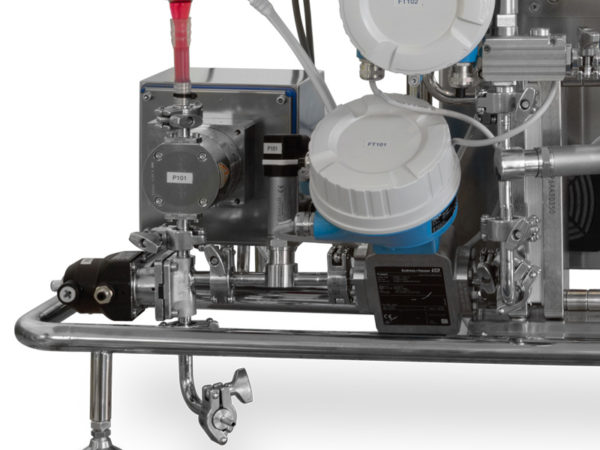

- The control cabinet includes all the functions for parameters measurement and control: Modbus digital sensors, wireless connection, easy load pumps, recirculation vessels and valves module conveniently located.

- Powerful and accurate brushless motor, from 1 to 2000 RPM.

- Flexible filters holders.

- Small footprint to maximise lab space efficiency.

- Integrated NPW test.

- Optional filtrate flow control.

- Innovative filter history management.

Downloads

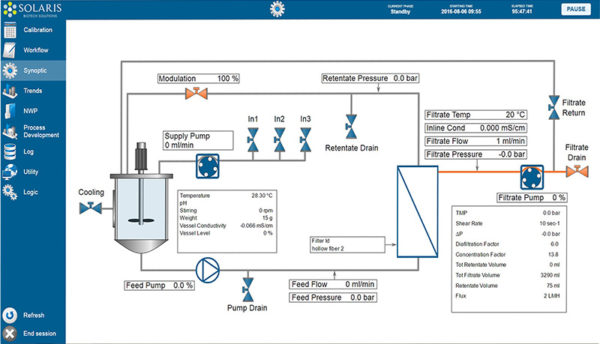

Solaris KRONOS TFF Software

- Galileo software: SCADA supervisory Lab View

- Included in the equipment supply

- CFR21 part 11 compliant

- User-friendly process management

- Automated process sequence

- All data trends

- Automated NWP test

- Automated process development module

- Filter management module

- Remote access via PC, tablet and smartphone

- Remote control for after sale assistance

KRONOS Options for TFF Membranes

Solaris technicians can suggest the customer the best membranes available on the market (in terms of materials, geometrical configuration and operative parameters) for your Tangential Flow Filtration system.

- concentrate with the best efficiency

- avoid the problem of the gel layer

- increase the efficiency in Diafiltration

More on Solaris

Solaris Biotech benchtop fermenters and bioreactors offer efficient platforms for R&D and product development applications. Their broad range of products are flexible and easy to use, ensuring there is always a solution specific to your needs and requirements – from research scale of a few hundred ml up to cGMP production of > 2000L.

Benefits include compact and user friendly designs, parallel software platform, up-to-date and open communication protocols.

The product range is used in universities, schools and research centres, as well as in pharma, nutraceutical, cosmeceutical, chemical, agricultural, and food and beverage industries, not to mention bioplastics and biofuels applications.

Solaris Tangential Flow Filtration (TFF) systems, fully automated within the Kronos product line, combine industrial elements and a compact design. For larger scale TFF applications open to customisation, consider the Tytan platform.