Description

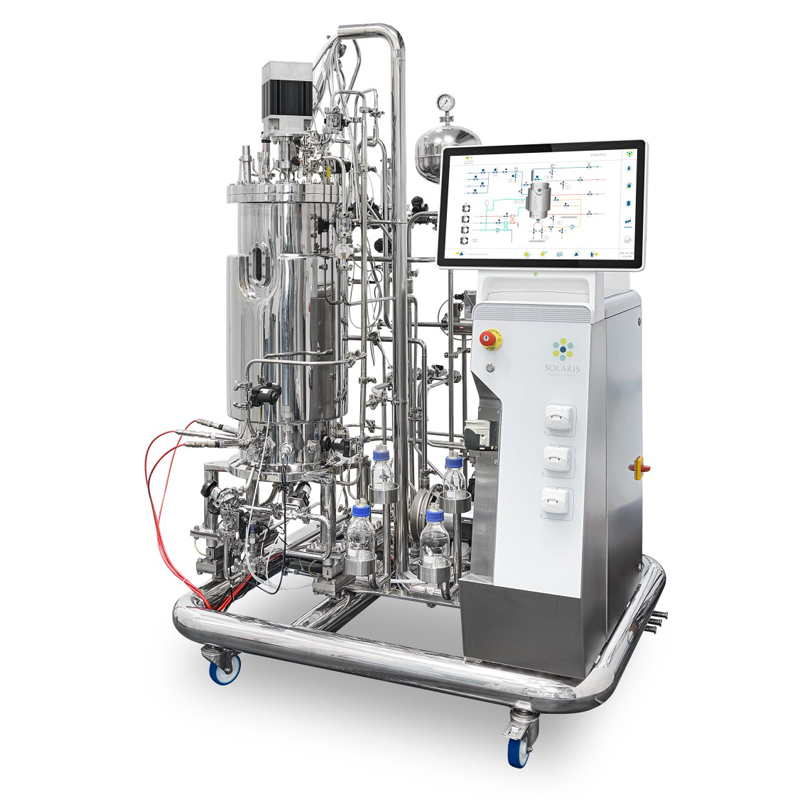

Solaris GENESIS: Single and Parallel Standard SIP Fermenter/Bioreactor

- Available from 7.5 to 20 L total volume

- Automatic sterilisation by steam or electric heaters

- Ideal for microbial fermentation as well as animal, plant and insect cell cultivation

- Applications include:

- Process development and optimisation

- Scale up/down studies

- Basic research

Automation and Software

Innovative SCADA software LEONARDO 3.0: a smart and user-friendly controller designed to provide a high level of automated management of the fermentation/cultivation processes.

- 24” coloured touch screen industrial HMI.

- Included in the equipment supply.

- Data extraction in .csv format.

- Remote access via PC, tablet or smartphone, with QR code scanning or dedicated portal.

- Remote control for after sale assistance.

Features

- 6 different volumes: 30 L, 50 L, 75 L, 100 L, 150 L, 200 L. 3:1 H/D ratio.

- Finishing: mirror polished (internal and external).

- Double jacket (side/bottom), for higher heat transfer efficiency and optimal temperature control.

- Welded baffles.

- Modbus digital sensors.

- Stainless-steel industrial PCS LEM_2, with a selectable number of peristaltic pumps, choosing between Watson Marlow WM 114, WM 313 and WM 520.

- Parts in contact with the culture AISI 316 L, other parts AISI 304.

- Compact design.

- Bacteria (Toro sparger, Rushton impellers) and cell cultures (Sintered sparger, Marine impellers) configurations available.

- Wide range of measurement and control options for cell cultures and aerobic/anaerobic microbial fermentations, including temperature, pH, dO2, dCO2, redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells).

- Suitable for batch, fed-batch and continuous processes.

- Powerful and accurate (1 RPM) brushless motor, mounted on top.

Benefits

- Different gas mixing strategies with a selectable number of TMFCs or solenoid valves, for air, O2, CO2 and N2.

- Up to 2 steam bridges (re-sterilizable diaphragm valves for inoculum/feedings) can be added in option (with manual or automatic sterilization control).

- TK connection.

- Single mechanical seal. Double mechanical seal, with automatic lubrication though steam condensate loop available in option.

- Separate drains: cooling water return, condense drain to waste, hot condense return.

- Optional vessel empty sterilization.

- SALAS (Solaris Sterile Liquid Addition System) included in the standard configuration.

- Non-SIP sampling and harvest valves are included in the standard configuration. Steam SIP lines can be added in option. Manual or automatic sterilization.

- Tri-Clamp stainless steel piping.

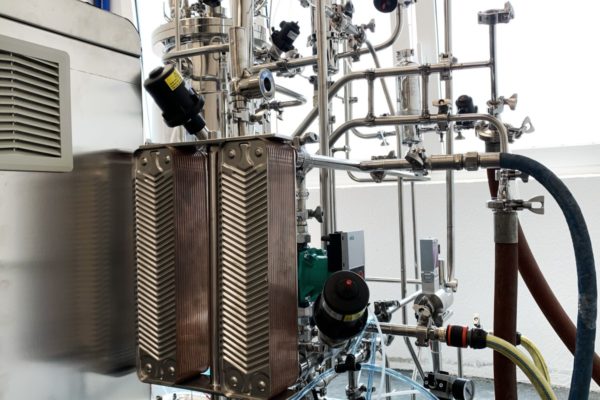

- Thermoregulation loop consisting of n.2 heat exchangers and recirculating pump.

- Gravimetric flow control (option): feed rates controlled through weight measurement. CIP system options: n. of removable spray balls or integrated system (recirculating pump + n. of removable spray balls + software automation). N. of spray balls depending on vessel volume.

Downloads

More on Solaris

Solaris Biotech benchtop fermenters and bioreactors offer efficient platforms for R&D and product development applications. Their broad range of products are flexible and easy to use, ensuring there is always a solution specific to your needs and requirements – from research scale of a few hundred ml up to cGMP production of > 2000L.

Benefits include compact and user friendly designs, parallel software platform, up-to-date and open communication protocols.

The product range is used in universities, schools and research centres, as well as in pharma, nutraceutical, cosmeceutical, chemical, agricultural, and food and beverage industries, not to mention bioplastics and biofuels applications.

Solaris Tangential Flow Filtration (TFF) systems, fully automated within the Kronos product line, combine industrial elements and a compact design. For larger scale TFF applications open to customisation, consider the Tytan platform.